YOUR APPRENTICESHIP WITH US CREATES OPPORTUNITIES WITH A FUTURE

In the last 15 years, our departments have successfully trained a total of 119 apprentices in the following occupations:

- 68 cutting machine operators

- 36 surface coaters and

- 15 industrial clerks.

As an apprentice at Effgen Lapport Schleiftechnik, you will earn a recognised qualification and the opportunity to take up a full-time position with the company as a skilled worker. More than 90% of our former apprentices are still working in the company today.

Your advantages as an apprentice:

- Free employee shuttle to the workplace and back.

- The company provides you with personal and individualised work clothes.

- Regular trips (IAA, trade fairs) and events (such as driving safety training for novice drivers, barbecue evenings, etc.).

* All apprenticeships offered by Effgen Lapport Schleiftechnik are open to m/f/d applicants.

“I like the apprenticeship because the work is very varied. That’s because we make a wide variety of products. I also enjoy the friendly atmosphere and especially working in the new apprenticeship area.”

Leon Fritz,

Apprentice cutting machine operator

“The structured training provided by experienced trainers, as well as further opportunities for my professional development, have enabled me to build a successful career. I started as an apprentice and i am now a member of the executive board in a global company with many departments.”

Gerd Berend,

Industrial clerk Functional area: Logistics, customs, export control, authorised signatory, Member of the Executive Board.

Cutting machine operator

The job

- Your work keeps cars on the road, planes in the air and trains on the tracks. Your hands will help to create precision parts for products of all kinds and shapes.

- As a cutting machine operator, you will manufacture precision components from different materials using machining processes such as turning, milling or grinding.

- As a cutting machine operator at Effgen Lapport Schleiftechnik, you will be working for a manufacturer of precision grinding tools. The highest standards of precision as well as the production of single and very small series components will ensure your work is varied.

- You will be responsible for ensuring that production runs like clockwork. From the beginning. Following the specifications of the design engineers, you will program the CNC machine for our precision tools. You will set up the machine, start production processes and monitor the dimensional accuracy of the parts produced.

- If something goes wrong, you will intervene. You will also be responsible for maintaining the machine because keeping your tools in good condition is just part of the job. And you will be responsible for your team.

Your profile

- You should have good grades in your school leaving certificate and strong marks in mathematics and technology.

- Reliability and accuracy in your work are essential.

- A good knowledge of maths is helpful for programming machines correctly – after all, the products you make require the highest levels of precision.

- A good understanding of technology is important because it helps you to understand how the machine functions, especially during inspection processes and Troubleshooting.

Your apprenticeship and subsequent career

- The apprenticeship lasts 3.5 years and is designed as a dual training programme, i.e. it takes place alternately in the company and the vocational school for technology in Idar-Oberstein. Cutting machine operator is recognised as a skilled occupation by the German Vocational Training Act (BBiG).

- During your apprenticeship you will specialise in one of the following areas: lathe systems, automated lathe systems, milling machine systems or grinding machine systems.

- If you prove yourself during the apprenticeship, a permanent position after your final examination is almost certain. More than 90 % of our former apprentices are still working for the company today.

- And if you want to achieve more, your new qualification opens many doors. For example, there are training courses in manufacturing technology and IT applications in the fields of electrical or mechanical engineering. Cutting machine operators can also undertake further training to qualify as cutting machine technicians, master craftsmen and trainers, or even study for an engineering degree.

Surface coater

The job

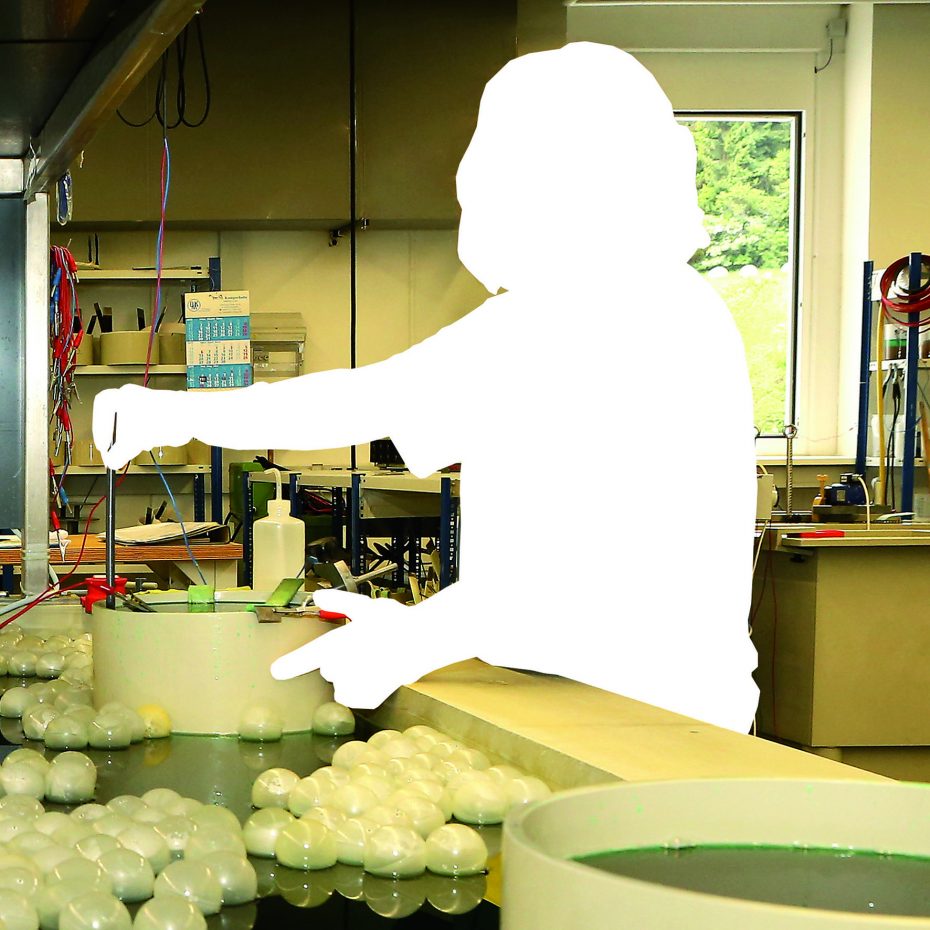

- Hot-dip galvanising, electroplating, colouring metals – your apprenticeship as a surface coater will be anything but dull. With your chemical knowledge, you will ensure that every product receives the correct metallic coating. After completing your apprenticeship, your skills will be in demand – in industry, trade professions, and all sorts of workshops. You will be a true specialist.

- As a surface coater at Effgen Lapport Schleiftechnik, you will be working for a manufacturer of precision grinding tools. The highest standards of precision as well as the production of single and very small series components will ensure your work is varied.

- Surface coaters were previously known as electroplaters. Electroplating is simply the process of protecting and upgrading surfaces using metals and electricity.

- Gloves on, safety goggles on and you will turn dull workpieces into shiny, high-performance grinding tools by coating them with nickel and abrasive grains of diamond or cubic boron nitride. You will grind, polish and clean your workpieces, record and keep track of all the processes, check measuring instruments and analyse the chemical baths used for electroplating.

Your profile

- You should have good grades in your school leaving certificate and strong marks in chemistry and technology.

- You should have a good sense of responsibility and a love of accuracy because you will be handling hazardous materials and sensitive workpieces.

- An interest in chemistry and mathematics are essential because you will need mathematical skills to calculate specific proportions.

Your apprenticeship and subsequent career

- The apprenticeship lasts 3 years and is designed as a dual training programme, i.e. you will complete training blocks that alternate between the company and the vocational school in Schwäbisch-Gmünd. Surface coater is recognised as a skilled occupation by the German Vocational Training Act (BBiG) and the German Crafts and Trade Code (HwO).

- During your apprenticeship, you will learn everything about the chemical processes, the treatment of the metals, and environmental protection.

- If you prove yourself during the apprenticeship, a permanent position after your final examination is almost certain. More than 90% of our former apprentices are still working for the company today.

- And if you want to achieve more, your new qualification opens many doors: you can continue your training to become a technical specialist, state-certified technician, or even study for a degree in materials technology or materials science. Naturally, you can also qualify as a master craftsman and thus become a trainer yourself.

Industrial clerk

The job

- Industrial clerks are employed in almost every sector of business and trained to perform all sorts of commercial tasks. So your apprenticeship will ensure you are a real all-rounder. You will take responsibility for the planning, execution and controlling of various commercial tasks.

- As an industrial clerk at Effgen Lapport Schleiftechnik, you will work in a functional area of the company, such as materials management, sales, purchasing, human resources office or the finance and accounting department.

- Your work will ensure that the business runs like clockwork. For example, you will work on a wide variety of business transactions, or produce offers and statistics. In addition, you will check machine usage plans, coordinate production orders, or monitor inventory levels.

- In meetings with colleagues, you will discuss sales promotions or purchasing strategies.

Your profile

- You have passed at least your intermediate school leaving certificate (Sekundarabschluss I – roughly equivalent to GCSE in the UK) and have strengths in mathematics, German, and a foreign language.

- You have a natural sense of responsibility when dealing with confidential commercial data and a friendly, open-minded manner with customers and suppliers.

- You are a good team player and able to work together with your colleagues to overcome the challenges of everyday business life.

Your apprenticeship and subsequent career

- The apprenticeship lasts 3 years and is designed as a dual training programme, i.e. training blocks alternate between the company and the vocational school for business in Idar-Oberstein. Industrial clerk is recognised as a skilled occupation by the Chamber of Industry and Commerce (IHK).

- During the practical phases of your training, you will learn about all the commercial areas of our business. You will produce offers, calculate the prices of our products, procure raw materials, understand the relationships and connections in the value chain, and much more.

- If you prove yourself during the apprenticeship, a permanent position after your final examination is almost certain. More than 90% of our former apprentices are still working for the company today.

- And if you want to achieve more, your new qualification opens many doors. Typical professional development opportunities for industrial clerks at EFFGEN Schleiftechnik include: Fachkaufmann, Fachwirt, Betriebswirt (German commercial professions requiring higher qualifications), trainer, certified accountant, university degree in economics, field sales representative or application engineer.

Our apprentices and their company

Send us your application documents:

Günter Effgen GmbH

Am Teich 3-5

55756 Herrstein | Germany

Telephone: +49 (0) 67 85 – 18 – 0

Platzhalter

Lapport Schleiftechnik GmbH

Rosenhofstraße 55

67677 Enkenbach-Alsenborn | Germany

Telephone: + 49 (0) 63 03 – 92 11 – 0

Fax: + 49 (0) 63 03 – 66 25